How to convert uniform linear motion(mm/s) to uniform rotary motion(deg/s). I.e. table saw blade tilt mechanism. Something like reversed Scotch yoke mechnism.

Asked

Active

Viewed 629 times

0

-

1What constraints? Full revolution? Pi radians? Continuous or reciprocating? Speed or accuracy? Scotch yoke will not be linear. See the Tchebychev Lambda Motion for one approach http://engineering.stackexchange.com/questions/13203/how-this-radio-knob-converting-a-rotation-into-a-straight-linear-motion/13213#13213 – user_1818839 Feb 22 '17 at 11:53

-

Like the saw, 90 degrees non-reciprocating, 1mm/s to 0,5 degree/s – Zveratko Feb 22 '17 at 16:56

2 Answers

1

However in a table saw tilt mechanism the rack is actually just a segment of a much) larger gear.

Howecer the scotch yoke is not uniform rotary to uniform linear, it is actually uniform rotary to sine linear. You can get rotary motion out of reciprocal motion using a crankshaft. You may need to add a flywheel to maintain the rotary momentum.

ratchet freak

- 5,741

- 18

- 19

-

are there any other mechanism without using geared wheel(or its segment). Using shafts only.Something like [this](https://www.youtube.com/watch?v=09jZsBDHalE) ? – Zveratko Feb 22 '17 at 10:16

-

1@Zveratko There's a good link from Brian Drummond in the comments to the question about linkages. The one in the answer is a classic. You can also look into four bar linkages and potentially find a design that works better for you (or make something similar to the one in that video). A problem with 4 bar linkages is that they will have some non-linearity. This is also discussed well in Brian's link. If you don't have to do full revolutions you may be able to constrain a linkage linearly. That's a reason why a rack & pinion is a good way to convert from rotation to translation. – JMac Feb 22 '17 at 21:42

0

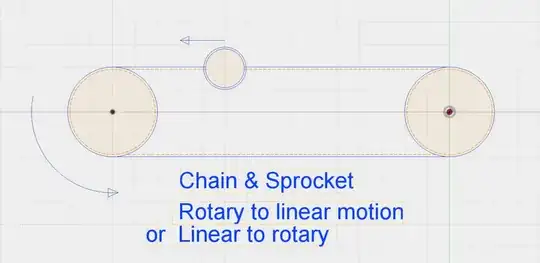

Well, to answer the question directly, a belt and pulley system precisely converts linear to rotary motion. Sprockets & chains, toothed belts, etc can drive in either direction.

Donald Gibson

- 1,076

- 6

- 11

-

The downside is that you have two "links" to driven wheel. Which complicates it technically, especialy when limited to 90 degrees output. The source gear must be geared down to enable the possibility to drive it by stepper motor, probably again with some gears.I'm looking for some "shafted" solution ommiting any gearing except for some lead screw with nut. – Zveratko Feb 24 '17 at 05:47