In my lawmower's motor plastic fan/ventilator on rotor has broken to few pieces

There are 2 small springs in fan's slots.

What is the purpose of these springs?

Are there any standards for such components?

Edit:

This is how it looks like in working motor:

And in my disassembling lawnmower some years ago:

Edit 2: Today I've got some other broken motor (burnt winding) but with fully operational fan so I was able to check it how it's working.

The simplest solutions are the best - this springs work as brake when motor is no longer supplied

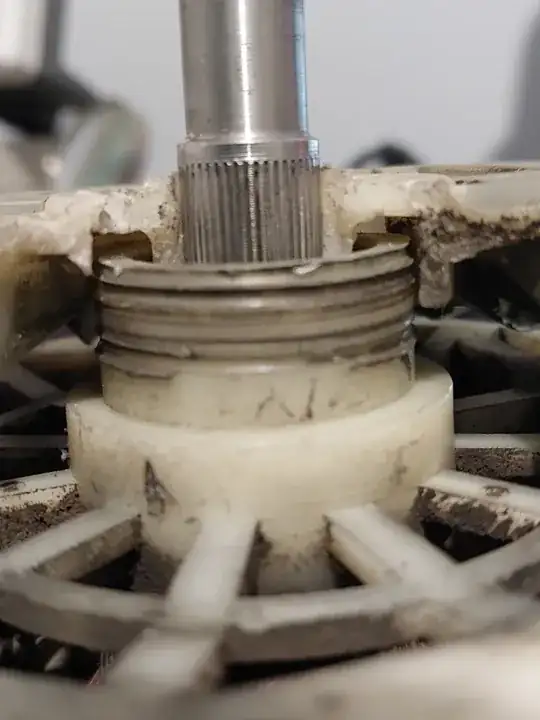

Here are some photos how fan is mounted on the shaft and where are springs (bottom view):

Springs are mounted inside fan and tightly touch fragment of the plastic on the top of stator. When motor starts spinning, centrifugal force "pushes" springs outside of stator so there is no sliding. When motor losts supply, rotor spins slower and springs start sliding of the plastic which stops rotor much faster than without it. Thanks to that we don't need to wait eternity to open basket and throw grass.

Due to friction between metal and plastic, it heats up and melts plastic on stator. I saw many small melted pieces around place where springs slide, so maybe my fan was destroyed by some bigger fragments of such melted pieces... I think manufacturer should put of the stator some rubber or some additional material between plastic and springs.

Anyway the topic can be closed. If you would have some more comments, feel free to write :)