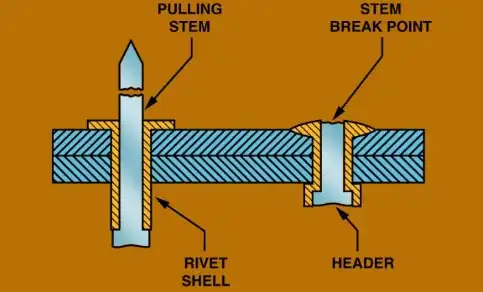

Pop Rivets are a fastener composed of two portions: the mandrel and the hat. To install a pop rivet a hole is drilled into the materials, and then the hat is placed into the hole. A rivet installation too is then slid onto the exposed mandrel end. As it begins pulling the mandrel, it deforms the back of the hat creating a strong and quick hold. Once a certain pressure is reached, the mandrel snaps leaving the hat deformed and in place.

Basically, and using the terminology from your diagram, the pulling stem is pulled until exceeding its capacity. During this pulling period the rivet shell deforms and creates a header on the rear of the installation. Once the pulling stem is pulled too tightly it will snap resulting in the stem break point being just below the surface of the rivet shell. This creates a firm secure hold.

Pop rivets are most commonly used for their quick installation process and because you only need access to one side of the installation materials earning them the name blind rivets.

Structural rivets are a bit different as there is a built in locking mechanism that ensure the mandrel portion that stays inside the rivet does not fall out but actually creates a secondary wall. This increases both the rivets strength and hold over time.