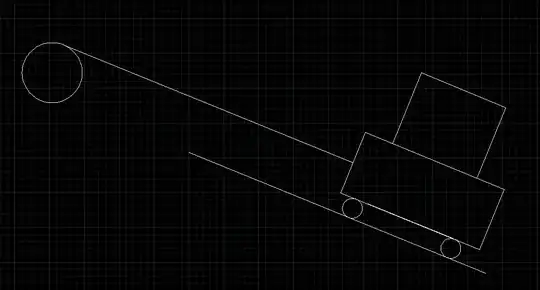

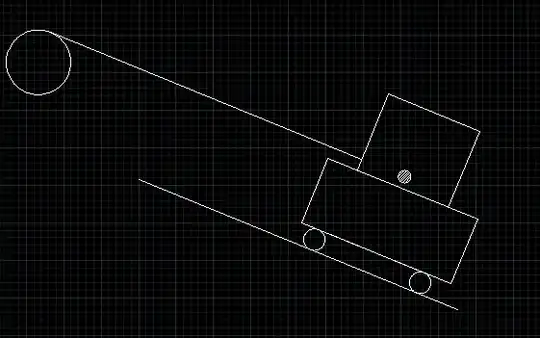

I'm working on a school project that requires us to build a compound machine with a mechanical advantage of 9. It should be able to lift a 10oz soup can three or more inches by using the weight of fifteen pennies. My machine consists of an inclined plane with a mechanical advantage of 3.16 (base is 12 in, height is 4 in), a travelling pulley system with a mechanical advantage of 2, and a wheel and axle system with a mechanical advantage ~3.

The total mechanical advantage should be 19, but when I put the weights on the system, it turns out that I need 45 pennies to lift the can, which means my mechanical advantage is 3. I checked for sources of friction, but I couldn't find any of note. I could add a second pulley to increase the MA, but I'd prefer to fix the problem instead of implementing a patch-up solution. Any help would be greatly appreciated.