I'm used to calculate the minimum radius required for bending operations on both aluminum and steel sheets, given the following parameters: https://imgur.com/a/7akHC

Problem statement:

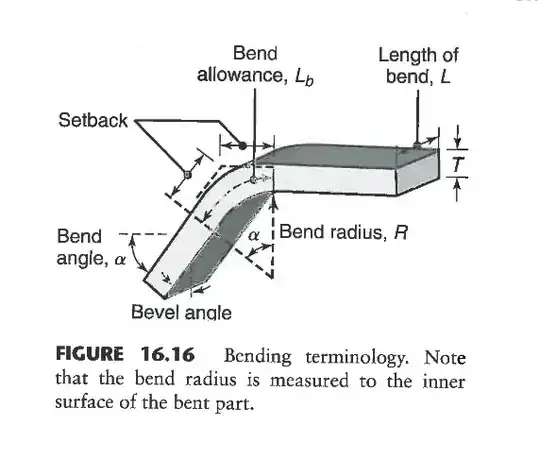

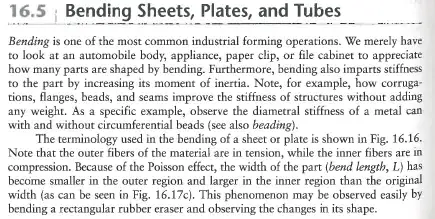

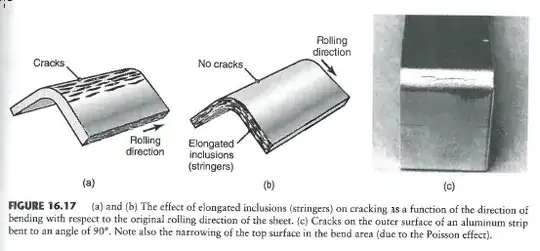

For a sheet metal stock with inch thickness, determine the minimum tool radius for both the steel and aluminum alloys that will not tear the material. Assume the sheet of material is in pure bending (i.e., no additional tension is applied during forming).

I have already learned about the following formulas:

- R = 1/k

- k(y) = e(y) / (h/2)

- e(y) = k.y

Given that R = 1/k, the next step is to find the maximum curvature k for each sheet.

The problem is that I don't know how to find the maximum curvature, and I'm still stuck.

Any thoughts?