LABVIEW can be easily be used for ME related experimentation.

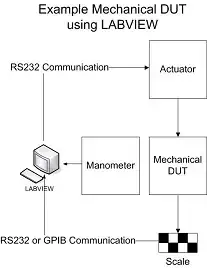

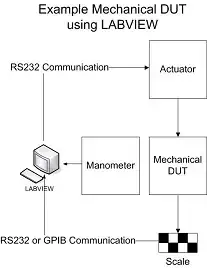

One such example would be to use an actuating mechanism to exercise a user interface on a mechanical DUT, which dispense a specific material quantity into a holding container. The weight of the material is measured using a weighing scale which communicates to a computer or controller. Also the test system also includes a digital manometer.

LABVIEW commands the actuator via RS232, and the weight of the material is captured using a scale. The weight data is communicated back to LABVIEW via RS232 serial communication.

This is an example of using basic tools to develop fairly complex ME experiment,both electrical and mechanical tools.

Limitation of LABVIEW

- Labview is a very capable tool for bench top experimentation either in ME or EE environment. To the most part capability of the tools is limited by users understanding and experience of the LABVIEW software and other tools.

- Labview’s graphical programming environment doesn't blend with the traditional structured or OOP programming environment. Therefore maintenance and enhancement is a limitation in a traditional sense. National Instrument will argue against my opinion.

- Labview offers basic program structures such as for loops, if then else, and while loops. This is sufficient for typical basic bench top testing software. But Labview has limitation in implementing advance structure like a binary search tree or recursion. This can be done, but not too elegant.

With the growth in LABVIEW, it is almost necessary to have fairly modern computer to use LABVIEW software. But with currently a good enough computer can be purchased for a bargain.

In summary, limitation is mostly the skill of the LABVIEW user.

References: