I would like to begin a case study in structural design using bamboo, which has currently become available to me. The design instance I would like to structurally copy is the Rogue RM-6 "Monster Rack" and a simple bench. Knowing that bamboo is used in scaffolding there must be details on structural reinforcement when binding stems together to make a structure. I would like to apply these kinds of principles to this rack design making necessary modifications where compromise is necessary. I do not know a good source to learn how make such structural binding techniques, so I thought to ask here if anyone here knows of one.

Asked

Active

Viewed 211 times

3

-

Assuming you will be using the bamboo in its natural form, (long tubes), why dont you just use standard joining techniques that you would use for any wooden structure, bamboo is really just a hard wood with a high silica content. – William Hird Nov 28 '17 at 23:18

-

Yes, long, unseasoned tubes. 20' tall 3"/4" diameter base tapering to about a quarter inch. What is "standard joining," in your opinion, @WilliamHird? – Nov 28 '17 at 23:25

-

1Welcome to Engineering! This looks like a [resource-hunting question](http://meta.engineering.stackexchange.com/q/10/1832). Such questions are prone to becoming out-dated, and are therefore considered off-topic for this site. – Wasabi Nov 29 '17 at 00:28

-

Do some research in the coutries that use bamboo for scaffolding and many other things. – Solar Mike Nov 29 '17 at 07:56

-

1@WilliamHird: Bamboo being mostly hollow tubes doesn't really work well for standard wood joining techniques like dovetail cuts. – SF. Nov 29 '17 at 15:11

-

I'd agree though. Instead of asking for sources on these techniques, just ask about these techniques. I'm fairly sure there's just a couple typical knots and a set of standard binding materials - the basics would fit an answer here. – SF. Nov 29 '17 at 15:14

-

@SF: I was just talking about joining techniques in general. Of course you would have to do something like mill flats on tubes so that you can face glue them together with a nice adhesive like West System's G-Flex. After the glue dries you would then reinforce the glue joint with screws or dowel pins. – William Hird Nov 30 '17 at 14:29

-

@WilliamHird: AFAIK, bamboo for scaffoldings, structural loads etc is about universally *tied*, using some kinds of string/fibre/rope. Glue, screws, dowel pins etc are only applied to decorative items where the rope would be considered unsightly, meanwhile structural loads are much weaker. (bamboo splinters length-wise very easily, so any techniques that pierce the tube really compromise its durability). – SF. Nov 30 '17 at 14:50

-

@SF: Well if you "must" tie them, why not use something strong like steel hose clamps in a cris-cross pattern. – William Hird Nov 30 '17 at 19:27

-

@WilliamHird: Distribution of load over the bamboo surface. If you use rigid clamps, you're likely to either smash the bamboo or get a slippage length-wise. A loop of some cord will distribute the load on the entire circumference (which the pipe structure will withstand neatly, unlike being squeezed in one axis only), and multiple loops will distribute load and friction over large surface. You're still thinking of bamboo as rigid bars, while it's quite brittle to uneven lateral loads. – SF. Dec 01 '17 at 00:47

-

@SF: A hose clamp is a loop that distributes the load around the circumference of the bamboo, not really making sense of your last comment. – William Hird Dec 01 '17 at 07:33

-

@WilliamHird: Okay if it's a flexible clamp. If you use rigid clamps like these: [1](https://www.hosecoupling.com/product/hose-clamps-double-bolt-clamps/) [2](https://www.lsengineers.co.uk/malleable-hose-clamp-1.html) it's a different matter. – SF. Dec 01 '17 at 09:36

-

One other alternative is to use steel tie wraps like the ones used to bundle electrical wires, these are much thinner and more flexible than hose clamps or maybe the OP can use some clever combination of both . – William Hird Dec 01 '17 at 15:57

1 Answers

4

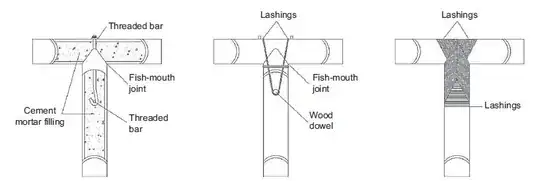

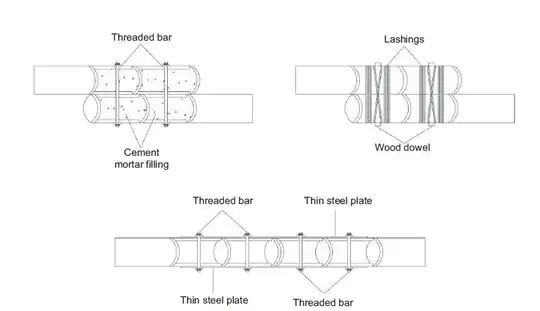

Bamboo in its natural shape is very prone to splitting. Having any kind of hole will reduce its high bending strength resistance significantly.

In addition, bamboo culm does not have a constant cross-section in the longitudinal direction, makes it harder to create a reliable bond. J.F. Correal "Bamboo design and construction" has few suggestions for bamboo connections. the following are few of the typically used and suggested connections.

Niaz

- 41

- 3