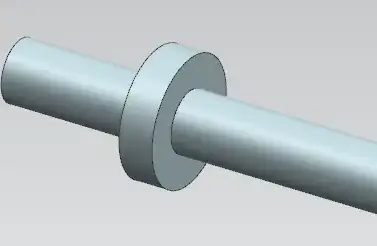

Let’s say I have a circular rod that has an outside lip with a larger diameter and certain height. The rod moves axially, and the intent of the lip is to mechanically stop the rod at a maximum axial displacement. How would I calculate the maximum static axial force I could apply to the rod before the lip shears off of the rod?

I have a pretty good understanding of how to apply this problem in a simple cantilevered beam with a load orthogonal to the beam surface that provides a shear stress, however I can’t seem to wrap my head around this kind of problem, especially regarding second moment of area with a cross section that is radial instead of on a constant plane. As far as I can tell, the process is:

- Draw a FBD to find resultant forces on the shaft.

- Determine the resultant normal and shear stresses due to axial, shear, torsion, and bending forces.

- Use Mohr’s circle to determine sigma max, sigma min, and tau max.

- Apply one of the failure criteria for brittle/ductile materials.

Can anyone provide some guidance or direction?