One of the key design characteristics of a gear is its tooth profile. This is typically based on what is called an Involute Curve, and the shape of the tooth is designed to maintain consistent force through the tooth at its pitch line during rotation and to minimize backlash within the series. The interweaving of the teeth themselves is referred to as the gears "meshing" and the curvature of the teeth allow them to clear one another as the gear rotates.

This Wikipedia illustration give a good visualization of how the teeth actually "mesh": https://upload.wikimedia.org/wikipedia/commons/c/c2/Involute_wheel.gif

I'd also take a look at http://Geargenerator.com which give a great animation of gear tooth interaction and allows you to vary the tooth parameters to see how the shape of the teeth interact.

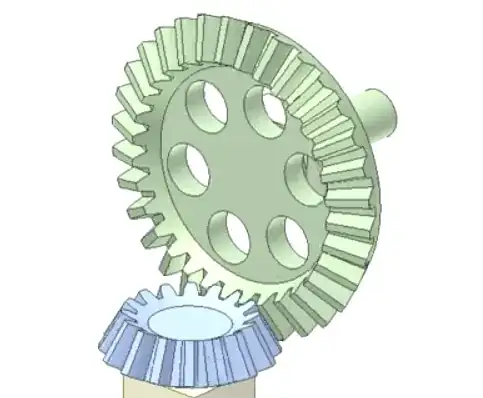

Now, reconsidering your original question, you can easily see that simply putting two flat spur gears at a right angle to one another would defeat the entire concept of proper gear "mesh" and in fact the teeth would bind because they wouldn't "fit" into one another.

A set of bevel gears solves this problem by placing the teeth on an angle so that they face one another and mesh properly!