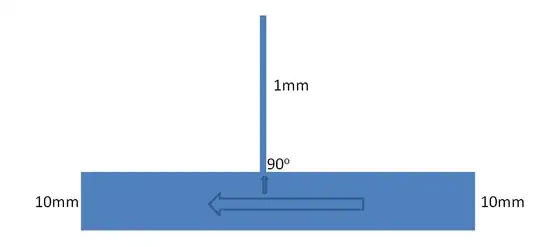

I have been trying to model a complex pipe network recently and have come across something I can't find any information on. In my model, I have been assigning equivalent lengths of pipe to various fittings, but I commonly encounter fittings such as this:

Inlet to T: 10mm diameter pipe

t-through: 10mm diameter pipe

t-branch: 1mm diameter pipe

Essentially I have a T junction where the branch is also a sudden contraction, but the dominant flow direction is perpendicular to the branch. Does anybody know a method of calculating equivalent length of pipe in a case like this?

I don't think a regular vena contracta, as described by normal theory for sudden contractions, would occur in the 1mm branch, since it is perpendicular to the main flow and not coaxial with the main 10mm pipe.

But I have various instances where this occurs, and the amount of the contraction varies (e.g. the branch pipes can be 1,2 or 5mm) but the normal method of equivalent pipe length for a t-junction does not account for the changing area. I need something that will account for it.