Short answer

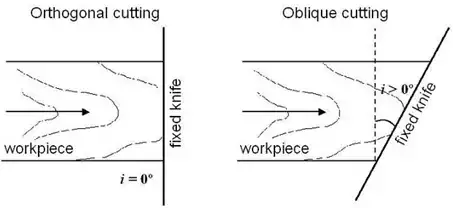

Orthogonal cutting increases pressure and decreases tool life. Thus isn't used if aim isn't cutting. Lathe operation is a shaping operation, not a cutting operation most of the time.

Long answer

Orthogonal cutting isn't suitable because

- Cutting forces act on a smaller area of cutting surface on tool if orthogonal cutting is employed so it increases wear on tool tip. However oblique cutting distribute cutting forces to greater area thus increases tool life.

- You usually don't want corners on your part. Corners reduce strenght and you want chamfers.

- Chip flow is another problem in orthogonal cutting.

- It's not possible to obtain perfect tool tip for orthogonal cutting, so addition of ploughing force increases total cutting force.

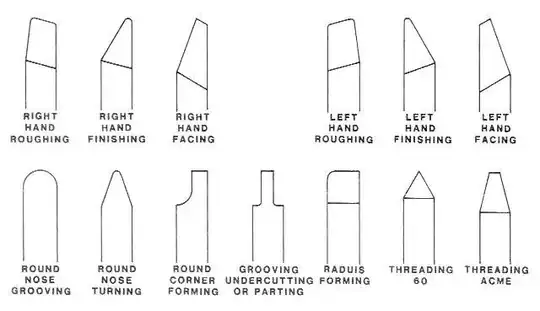

However, if you're trying to cut off a part you'll use orthogonal cutting. Below are some examples of cutting tool shapes

Check Fundamentals of Metal Cutting and Machine Tools pages 117-139 which are accessible in Google Books.