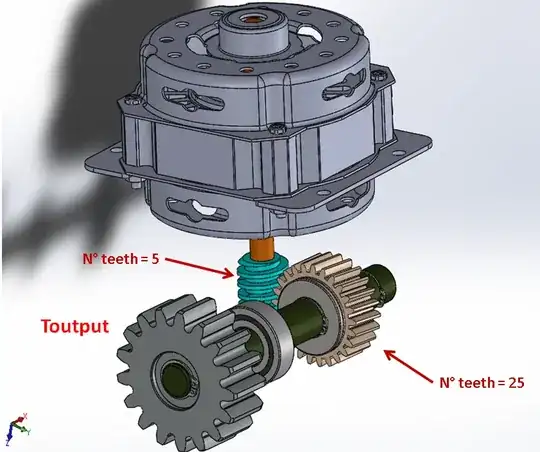

The transmission ratio is related to the number of teeth on the worm gear, and the number of starts on the worm.

In your case, $$i=\frac{z_{worm\ gear}}{z_{worm}}=\frac{25}{1}=25$$.

This means that you have a reduction of $25:1$, so, assuming $100\%$ efficiency, you would expect your output Torque to be 25 times higher than your input torque, and your output speed to be a twentyfifth of your input speed. $$T_{output}=25T_{input}\ ,\ \omega_{output}=\frac{\omega_{input}}{25}$$

This relationship will hold pretty much true for the speed ratio, although you will find that resistance from the gears and the load will reduce your input speed to be lower than you have calculated above. You can get an estimate for the expected motor speed by looking at its datasheet.

For torque, however, you need to account for lost power to e.g. friction.

According to: https://www.machinedesign.com/mechanical-drives/gear-efficiency-key-lower-drive-cost

Efficiency of a worm-gear speed reducer depends (in part) on its speed-reduction ratio. High-ratio units have a smaller gear-tooth lead (helix) angle, which causes more surface contact between them. This higher contact causes higher friction and lower efficiency. Typical worm-gear efficiencies range from 49% for a 300:1, double-reduction ratio, up to 90% for a 5:1, single-reduction ratio.

So, with your ratio of 25:1, it seems safe to guess at an efficiency around 80% as a starting point.

Looking at conservation of Power, including Losses,$$P_{in}=T_{in}\omega_{in}=T_{out}\omega_{out}+\left(0.2*P_{in}\right)$$

Therefore $$T_{out}=\frac{0.8*P_{in}}{\omega_{out}}=\frac{25\left(0.8*P_{in}\right)}{\omega_{in}}=\frac{20*P_{in}}{\omega_{in}}$$

Re: your goal of moving a 600kg gate - you need to consider acceleration as well as just 'cruising speed' when doing your power calculations.