So, I am working with FBG sensors and I have read that those sensors need to be re-calibrated every 10 years to get accurate measurements. But no where on the internet (AFAIK) is it explained why every 10 years it has to be re-calibrated and why.

-

Is it a manufacturer recommendation? Have you contacted them? – Solar Mike Aug 31 '19 at 13:27

-

Mechanical loading and thermal cycling may cause the material to creep and therefore change the grating line separation. – alephzero Aug 31 '19 at 13:33

-

For Solar Mike. The sensors are glued on the road of steel in an bridge structure – LinkCoder Aug 31 '19 at 16:57

-

@LinkCoder did you contact the manufacturer, glued or not? – Solar Mike Sep 01 '19 at 07:56

-

@ Solar Mike ... Not ! just i would like to know what the reasons to re calibration .. the answer of alephzero was ok.. more information .. let me know .. thanks! – LinkCoder Sep 01 '19 at 13:38

-

To be honest it is probably one of those ISO 200 Hang ups as I call them. Many things are a little out of the ordinary. Your fiber optics being one of them. Most things need re calibrating as ALEPHZERO points out Mechanical loading and thermal cycling electrical connection degragation etc. However your silicon stuff to be honest probably never needs to be recalibrated. – Brad Sep 02 '19 at 09:37

-

However the Auditor for the ISO 2000 and it's children, need a box to be ticked so we get things that have seemingly no reason just because it is easier to conform with bureaucracy than fight it. This sounds strange I know, but it happens everyday. – Brad Sep 02 '19 at 09:48

-

You should explain the FGB initialisation in your question for reader benefit. – Transistor May 27 '20 at 20:34

-

to find the reasons for recal, if you don't accept manufacturer's reasoning try using a thousand and see what happens 10 yrs later? There is usually only one reason for re-cal- that measurements may be invalid. Even with regular re-cal measurements may be invalid to some error bounds. How much error are you willing to accept? – Abel Sep 20 '21 at 13:22

2 Answers

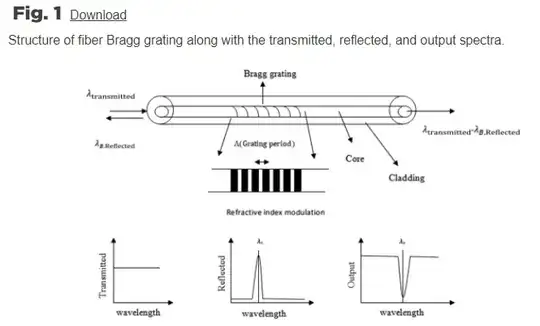

Theory of Fiber Bragg Gratings

FBG technology is one of the most admired choices of optical fiber sensors due to their simple manufacturing and relatively strong reflected signal. FBGs are formed by a periodic modulation of the index of refraction of the fiber core along the longitudinal direction. They are the devices that are based on the principle of diffraction grating. By grating, it is meant that there is a periodic change in the core’s refractive index. When the light travels inside the grating structure, some portion of light gets reflected back from each grating plane. Figure 1 shows the structure of simple fiber Bragg grating. Every reflected portion of light combines to form one reflected beam of light, but this is possible only if Bragg condition is met. The Bragg condition is given as

$\lambda_B = 2\Lambda n_{eff}$

where Λ is the grating period that forms the distance between two adjacent grating planes, $n_{eff}$ is the effective core refractive index, and $\lambda_B$ is the Bragg wavelength. When Bragg condition is met, all the reflected light constructively adds up to form backward reflected peak whose central wavelength is given by $\lambda_B$. The grating structure that follows Bragg condition works as a mirror that reflects selected wavelength $\lambda_B$ and transmits the remaining. If the condition is not satisfied, all the reflections from the grating planes will go out of phase and cancels out, therefore no reflection can be observed.

Whenever dealing with a device that calculates "period" and measures "wavelength", the requirement on periodic "calibration" seems to be unavoidable.

Fiber Bragg grating sensors for monitoring of physical parameters: a comprehensive review

- 7,917

- 3

- 8

- 27

Fiber Bragg Grating sensors can reflect a particular wavelength of a light beam or a selection of wavelength in a fiber optic by having the sensors fiber refractive index grated according to specifications to reflect the particular wavelength.

They are used for many applications in fiber optics such as add drop multiplexing and precision measurement of heat and stress.

Because the are precision tools each manufacturer has its own criteria of calibration and set up.

Here is a link to a good educational YouTube video.

You can click on the more link on the bottom of the video and read the physics involved and applications.

- 21,714

- 2

- 18

- 38