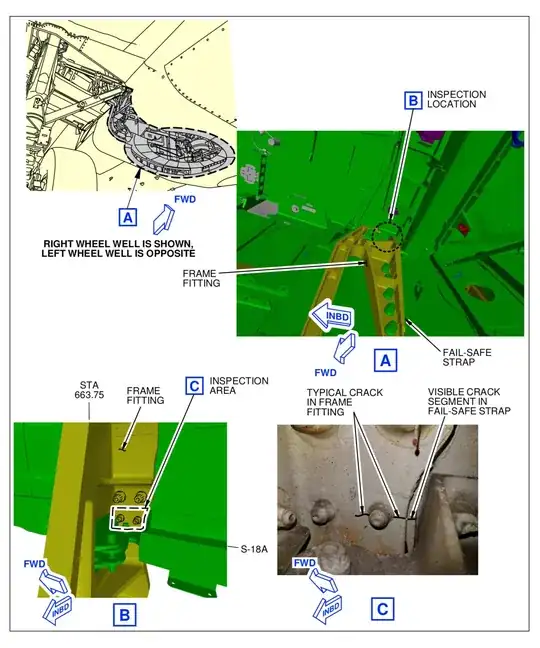

Boeing 737NG aircraft are currently being checked for cracking in the "pickle fork" assembly that attaches the fuselage to the wings. The affected joint has 4 fasteners that attach the fork to the wing. It's intended mostly to resist shear loads, as the fuselage twists relative to the wing. Boeing's inspection data is available at the FAA. That includes this image:

There is much discussion of this problem at the pilot's forum pprune.org Someone there states that the fasteners are meant to be an interference fit in holes that have been reamed and cold worked, and that the cracks have occurred because holes were drilled 6 thou oversize.

Why would this arrangement - 2 large fasteners and 2 small fasteners - have been chosen?

Boeing refer to the small fastener area as the "fail-safe strap". In what way might this be regarded as fail-safe?

Where is it appropriate to use interference fit fasteners in these specially prepared holes?

Why would drilling the holes oversize lead to the observed cracking?