I am currently working on a project that involves CFD simulation on ANSYS and i need some help as it has got me stuck. I am designing a faucet atomizer and it's functioning is similar to a nozzle.

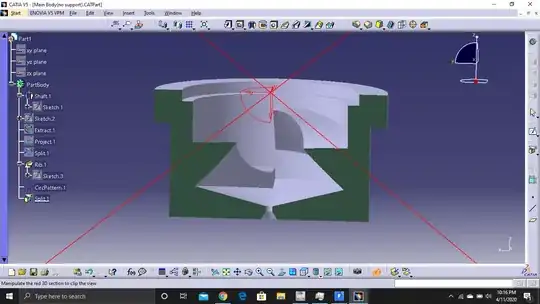

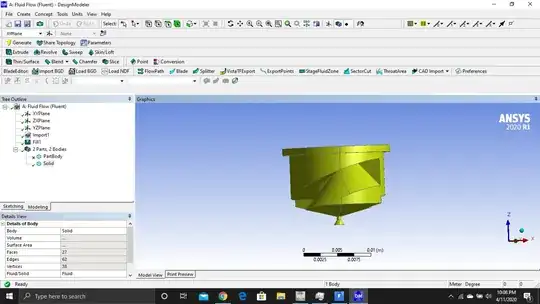

I have designed it on CATIA and am trying to analyse it on ANSYS Fluent.

I am using the following conditions:

-Pressure based solver, absolute velocity, steady flow

-Flow characteristics: Laminar at inlet, turbulent at outlet

-Boundary conditions: inlet velocity: 0.041 m/s, inlet pressure: 300000 Pa,outlet pressure: 0 Pa

-Fluid: water(liquid)

I have the following doubts:

1.)I read that turbulent models give accurate results even if flow is laminar but not vice versa so i chose turbulent but which turbulent model should i apply?

2.)My geometry has swirl, complex curves and rotational flow and i read that k-epsilon, k-omega models do not handle such flows and curves well so which model should i adopt(my geometry is very small in dimensions so swirl may not matter?).

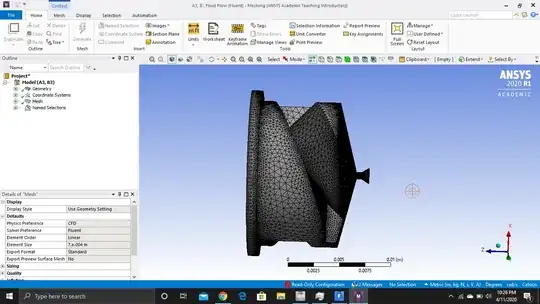

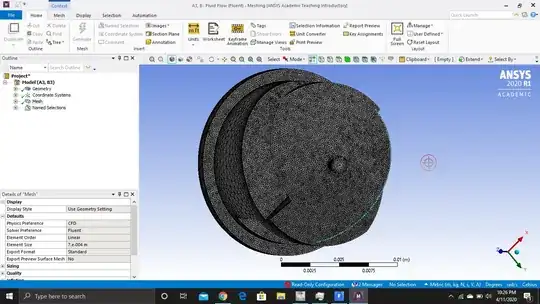

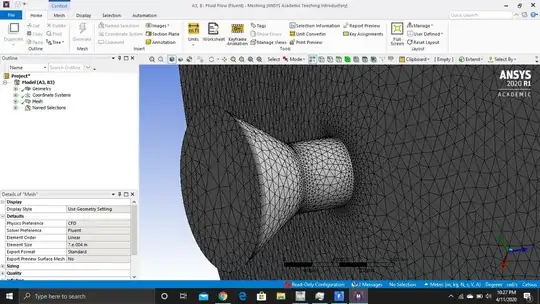

3.)How should i do the meshing of my model? I did it multiple times according to my understanding but due to some reason the solution didn't converge and diverged a couple of times as well. My system also does not have a lot of computational power hence less elements and nodes in mesh.

I am attaching some images of my geometry with sectional views, extracted volume and also the meshing done by me. Kindly take a look.

I will be able to share the geometry file with you if you require.

I will be very grateful if you can help me out.

Thanks