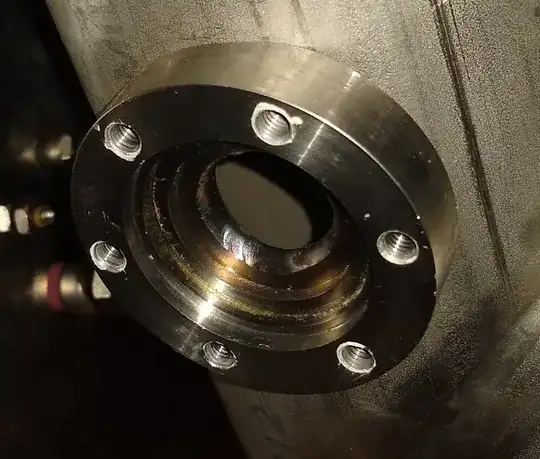

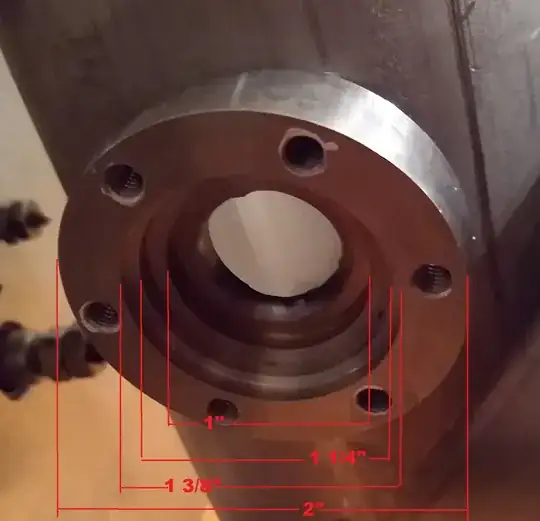

I have some experience with high vacuum so thought I put in my two cents along with what I was able to find on this particular flange. My first inclination was this is a custom unit and I have since checked with my vacuum community and they are of the same opinion.

Here is an exact quote from the most serior person in our group, "Looks custom. I would think an o-ring would fit over the shoulder in that thin groove and then get compressed when the two flanges are bolted together".

I have come across several unique flanges, especially when it comes to cathode gauges mounting to the chamber side. Here are a couple I just pulled off the shelf in the lab:

These will likely never see service again and are kept for the extremely unlikely event that they might be useful to someone down the road who could have them machined for their particular application.

Here are some photos of some connections that are currently installed on my 80's era General Ionex Tandem Accelerator:

The main point I am making is even though conflats and KFs are ubiquitous today, odd configurations were common a few decades ago and it is usually to deal with attaching the cathode gauge(s) to a custom vacuum chamber. In my experience these unusual pieces work quite well so long as the are in good condition, cleaned and installed properly with good and correctly sized o-rings.

If you need help locating a new o-ring - brass, copper, gold or otherwise, PM me; although it looks like yours is probably fine (assuming there wasn't also a rubber unit, but that is unlikely)

Good luck with your new system, and hope this helps!