Hello everyone :) This is my first post here so please excuse any of my mistakes.

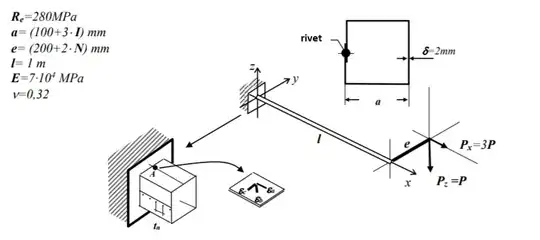

I’m having some difficulty with solving the following problem. Let us have a thin-walled square pipe exposed to bending, torsion and stretching (picture below). On the left side of the pipe, where sits the rivet, we will have shearing stress due to the twisting moment and the shearing force coming from the bending moment. At the exact same point we will also have normal stress coming from the streching and bending moment.

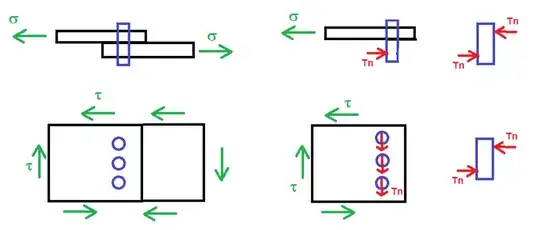

While calculating the force in each rivet, why do we only consider shearing stress without the normal one? I tried asking my professor. He replied with the second attached picture, which I don’t seem to understand. Any help is appreciated :)