Is there a calculation / rule of thumb that can determine a containers rough maximum negative pressure (vacuum) from it's rated internal pressure (assuming a single layer construction so there is no additional bracing preventing expansion).

As an example for a 50 litre stainless steel keg (cylindrical with convex end caps) with an integral 580 +/- 140 psi bursting disc.

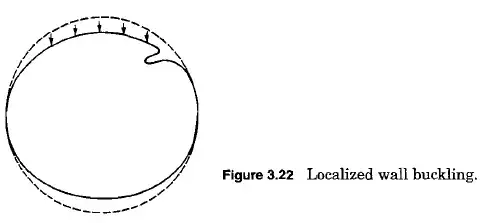

Would it be valid to assume that the weakest point (excluding the bursting disc) is calculated to withstand 400 psi of internal pressure (minus approx 14 psi from external atmosphere), directed outward so placing the material under tension. By reversing pressure differential (My logic says the weakest point still remains the same) the weak spot would come under a compressive force and the maximum pressure under vacuum would be a function of the ratio of that particular stainless steal grades tensile:compressive strength.

EDIT I just realized the bursting disc pressure is not relevant since that only indicates when a rupture would occur. In the reverse situation deformation into a flat can would occur well before then. However if instead of the bursting pressure you were to apply the 'Maximum working pressure' of 43.5 psi which presumably implies no deformation does the above apply?