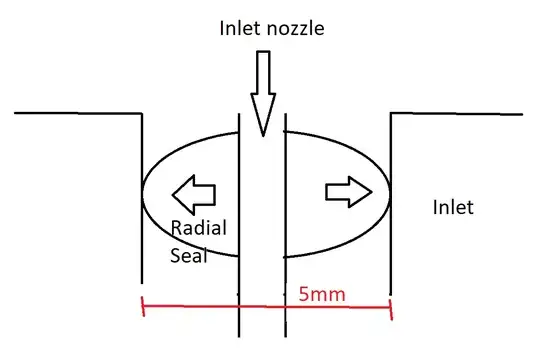

I'm trying to make a adaptor to fit a nozzle about 5mm wide which only applies pressure radially during insertion. Pushing in a standard O Ring would apply some force axially up or down the inlet due to friction.

The adaptor should seal in the inlet, before injecting gas to the object, see sketch. I can't change the object in any way, only the adaptor. Considering the size, can anyone suggest something off the shelf I can use for this? Or how I might make it at all?