I am looking into fabricating a steel tubing frame that needs to be dis/assembled (applies to many larger furniture like bed, shelving unit, wardrobe, cupboard, cabinet, ...).

What are the variants of the steel equivalent of a butt-joint and their pros/cons?

I have only found information on joints for construction steel (think skyscraper-sized double-T section) so far.

I have not found anything for closed sections in DIY sizes like 20/30/40 mm or 1 inch (easily available in hardware stores).

I am certain there must be something in literature. I might not be searching with the right terms.

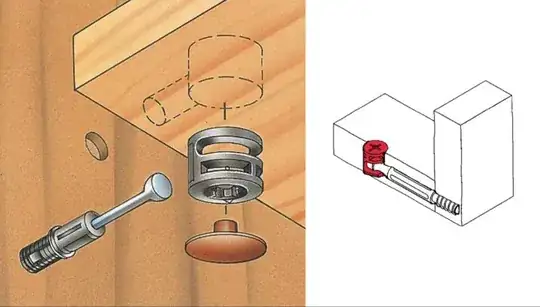

Ideally, the connectors would be "invisible", i.e. hidden inside the tubing (square or rectangular).

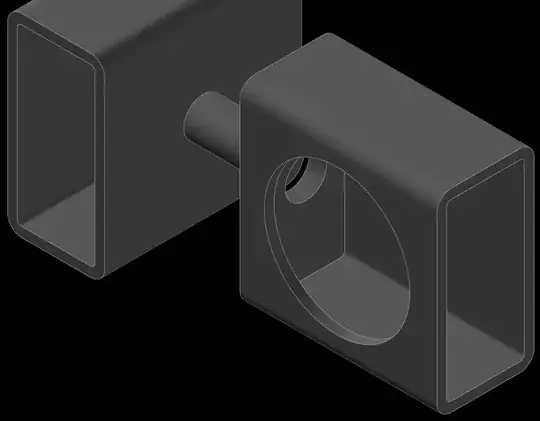

I am considering welding a bolt to one part and a cap onto the other - one hole for the bolt, and another to enable tightening a nut inside the tubing:

Drawbacks: only one fastener, bolts may be too small, assembly of the nut very "fiddly". Pros: does not weaken tubing (depending on load/bending moment).

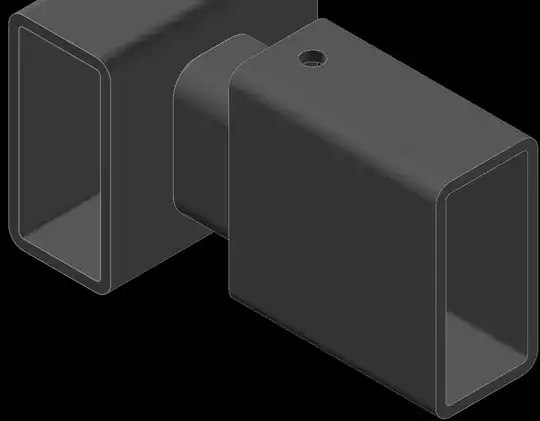

Another option:

Drawbacks: profile not tensioned, "snug" fit depends on availability and tolerances of tubing.

I'm also interested in connector-hardware made for this purpose.