It's not exactly my area of expertize and I've spent a couple hours ears deep in norms, and I'm not really sure if what I found is correct (the figure I found was to the order of 1$\mu$m).

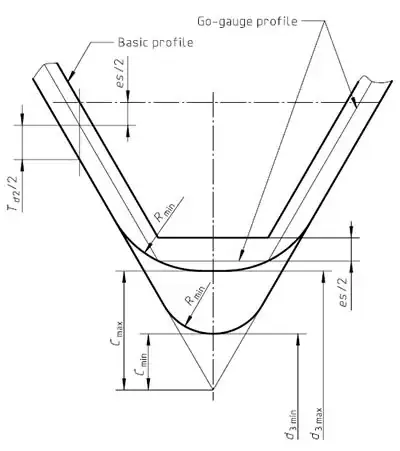

When using standard (off-the-shelf, not specialized) threaded pin / bolt and a matching nut for a lead-screw actuator, what degree of imprecision (free lengthwise movement of the actuator without the shaft turning) can I expect coming from the allowed technical tolerances of the thread? In other words, what amount of play can I expect between a threaded bolt and nut?

To be more specific, I realize there will be movement from lateral and longitudinal flexibility of the shaft; from its mounting bearings; from its axial twist against the drive; and probably quite a few other sources, but I'd like to know this specific factor - how much of a "give" or play can there be in a thread, allowing movement of the nut along the bolt without either of them turning.

I suspect that this changes with the shaft diameter, so a table or a method to calculate the amount of play for most common metric threads would be preferred for an answer. If that's too difficult or doesn't exist, I'm most interested in the value for M10 thread.