Hi I know this is a little bit of a strange one, but I’ve got a relatively cheap shelving rack that I bought to make good use of garage space.

I have included a pic, It’s footprint is 1220mm x 610mm and it currently has the standard 9mm thick particle board shelves. Although it’s been ok so far, there’s probably about 50kg on the middle shelf now (3D Printer + Laser Cutter) and I’m starting to see it bend slightly. I’m also planning to get a rotary attachment for the Laser which will add another 10kg or so.

It’s footprint is 1220mm x 610mm and it currently has the standard 9mm thick particle board shelves. Although it’s been ok so far, there’s probably about 50kg on the middle shelf now (3D Printer + Laser Cutter) and I’m starting to see it bend slightly. I’m also planning to get a rotary attachment for the Laser which will add another 10kg or so.

I want to strengthen it now so it’s not an issue long term. One idea I had was replacing the 9mm shelf with a 12mm MDF one as this is the thickest I could go while still having the shelf sit flush with the frame.

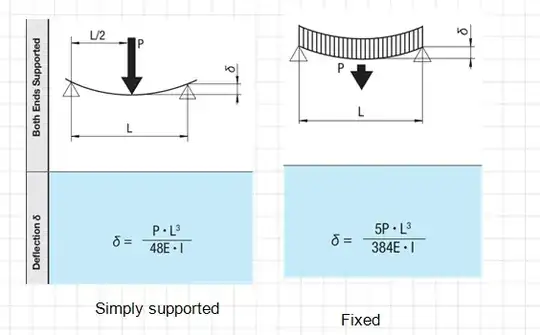

I know this will be significantly more rigid, but it will probably still sag over time and does not address the issue of the frame itself potentially bending as the shelves just sit into it. To counter this my plan was to have two sections of 2020 aluminium extrusion spanning the full width which would be positioned under the board about 1/3 in from the front and rear of the rack to evenly distribute the load. I would bolt these extrusions to the frame by tapping the ends. I would also add a couple of short extrusion lengths perpendicular to the long ones to tie them together for added stiffness.

Here comes the question: I want to use 2020 extrusion because is pretty cheap and easily available in the lengths I need. I believe I will provide plenty of strength/rigidity but my Dad doesn’t think it’ll make that much difference, and instead recommends 3030 extrusion. The problem is 3030 is much harder to get here and way more $$$.

How well would my 2020 solution work? Who is right?