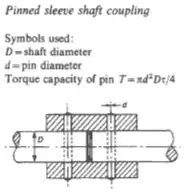

Does using multiple shear pins under a limiting torque case reduce the minimum required shear pin diameter for the coupling or is the complete load distributed over the shear pins regardless of the number of shear pins that are used?

-

Most torque should be taken by the coupling - shaft connection , not the pin ( or a keyway). – blacksmith37 May 25 '21 at 13:53

-

@blacksmith37 - I think a shear-pin design intended to limit torque by breaking, would be different from one intended to stay intact under all use cases... I suspect the first would need some clearance to make sure ~100% of the torque goes through the pins – Pete W May 25 '21 at 14:00

-

@PeteW if two pins were used with clearance (i.e. they were not pressfitted), I would be very nervous about designing the pins to half the torque. The clearance would (most likely) mean that one of the pins would engage sooner than the other and therefore will carry the majority of the torque. what do you think? – NMech May 25 '21 at 14:36

-

@NMech, I meant on the shaft OD, agree completely about the pin OD. sorry wasn't more clear – Pete W May 25 '21 at 15:28

-

@NMech The pin bearing all torque will most likely deform until the other one engages. Whether that deformation will be entirely in the elastic regime (harmless), plastic (reduce load-bearing capacity), or past completely shearing off depends on the materials and tolerances. – SF. May 26 '21 at 07:09

-

@SF I completely agree with you that's depended on tolerances and the material (brittle ductile), and I will also add on the type of loading that you have. If the loading changes dynamically, and you get "reversible" loading, then IMHO probably its best if you either use only one pin (because even the slightest clearance will allow kinetic energy to be accummulated and the result into a shock). Is that along the lines of your comment? – NMech May 26 '21 at 07:14

-

@NMech Yes - that, or very tight fit and exact tolerances (say, the pins shrunk using liquid nitrogen to fit; the holes in the coupling and the shaft drilled simultaneously while they are coupled to prevent placement errors), that way there's no play that would allow uneven distribution of load. – SF. May 26 '21 at 08:19

2 Answers

There is one pin in each shaft, so each pin takes the full load but in two places. This is known as double shear.

If you put 2 pins for each shaft then there would be 4 sections of pin taking the load so the pins would need re-sizing, otherwise they would be too strong and something else more expensive will break.

- 14,798

- 1

- 19

- 29

-

Hi @SolarMike , thank you for your reply. I have a follow-up question. If for example, I have a Ø80mm shaft which should be able to transfer 22,500Nm of torque. The minimum pin diameter for this case results in a steel pin (assuming shear strength = 370MPa) of 31mm, which is too big to be used for the mentioned shaft. What is the best approach in this situation? Increasing the diameter of the shaft is not really an option. – mech_engineer_12R May 25 '21 at 12:33

-

@mech_engineer_12R did you consider the double shear? ie 1 pin of 31mm in single shear or two sections of 15.5mm... Your image shows double shear... Also the material of the pin makes a difference. – Solar Mike May 25 '21 at 12:35

-

@mech_engineer_12R another option to carry such a high torque (22500) would be to use a keyway coupler. You can increase the length as much as you need – NMech May 25 '21 at 13:02

-

Due to torque, the pin will have two shearing planes at the opposite sides, each shear plane has a shear stress in the opposite direction of the other, I would think it is a single shear though. – r13 May 25 '21 at 19:11

Multiple pins would share the torque if they are radialy positioned and the sleeve bore holes are machined snug.

For example in your case if we have two perpendicular pins the shear on each end is 1/4 of total shear.

In many precisision applications such as aviation or heavy construction that they require multiple fasteners, even in complex geometry like the empenage of an airplane, the load is divded between the rivets. So each rivet takes a contributory load as a fraction of the total joint load.

- 21,714

- 2

- 18

- 38