I am new to this site and have a problem to solve in an area that I’m pretty lost in. I can usually figure stuff out with the help of the internet and some digging but not getting real traction so hoping some folks smarter than me can help!

I’ve built a sawmill and currently using an ATV winch to raise and lower the 350lb cutting head. It works great and very accurate but drawback include its very slow at around 24 rpm not to mention it must be drawing heavy amps so battery not lasting long.

I’m hoping to get some recommendations on a 12 V dc motor to select for my job. I don’t know what torque specs I need to adhere to let alone battery life and amp draw.

Specifications Include:

- 350lb weight to move on lineal axis

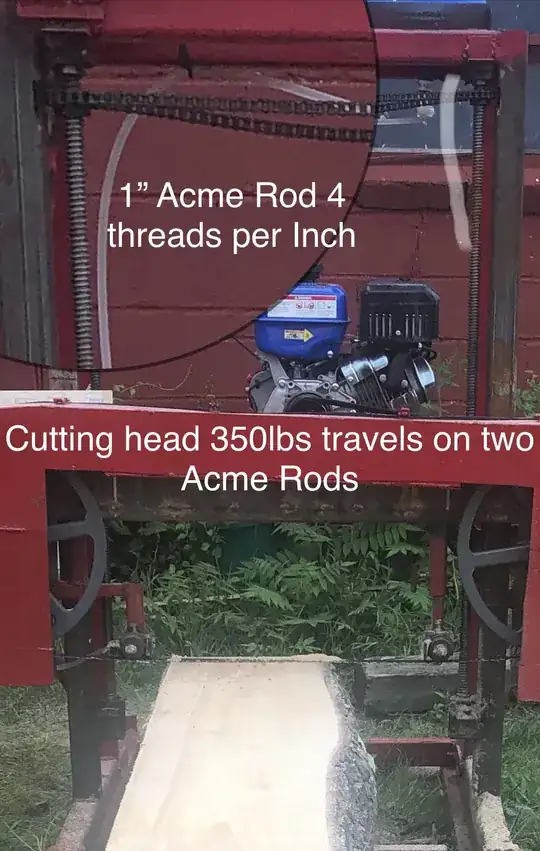

- Cutting head is welded to 1” Acme rod nuts

- Cutting head travels up and down on 2 Acme rods that are linked together with no 40 chain and sprockets.

- Acme rod is 1” diameter and 4 threads per inch

- max travel of head is around 30” up or down

- Typical motor activation might include turning on to raise or lower +/- 15 inches then followed by no activation for 2-3 minutes. Followed by 1-4” incremental changes up or down every 2-3 minutes.

- Battery should have capacity to run for 8-10 hours in the above mentioned cycling example.

Any recommendations for conserving battery life, torque needed to lift at 60-100 rpm? Force? What is force?

Thanks a ton for your help!!