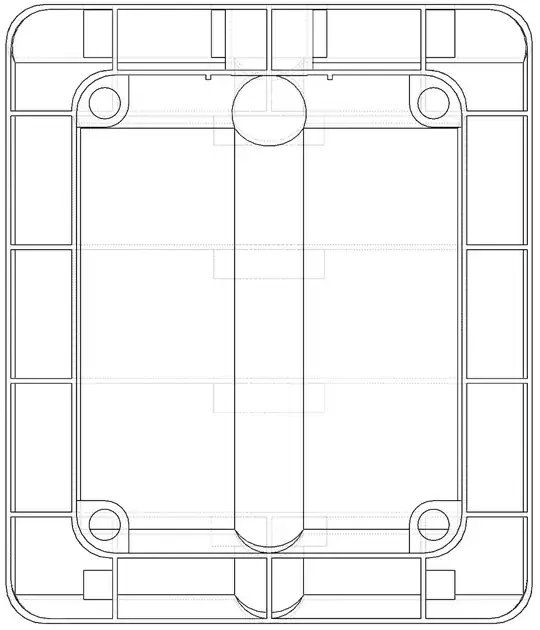

I have to mate two sections of something that could be reasonably approximated by a tube, though the material is stainless steel, and the cross-section is very non-circular, so I cannot use an o-ring. The walls are thin and the exterior must remain flush, so a flange/gasket is also out.

Are there established methods for pressure sealed mating of non-circular cross-sections?

Worth mentioning I will be able to compress the two pieces via internal screws.

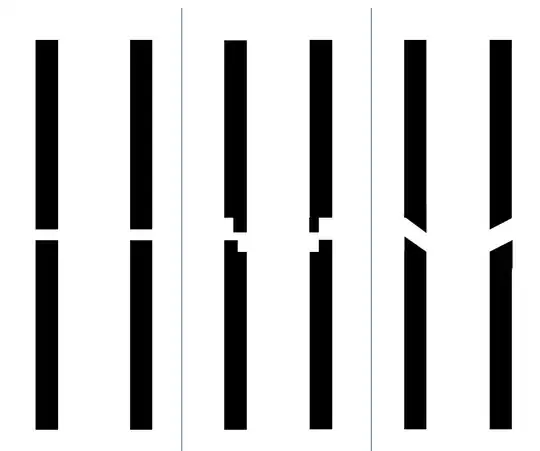

The diagram below shows some examples of what I might expect appropriate solutions may look like:

The left most is how the parts are now, with a flat mating surface. This would provide a terrible seal. The right two are possible solutions, but I would really like some precedence to justify my design.

Any guidance or references would be greatly appreciated.

EDIT: To address the comments, the wall thickness is 1/32". I will post a picture of the cross section below. Only the channels are pressurized against near vacuum in the internal volume and in the exterior. The gauge would be at max ~10 bar. There is no limitation on roughness of the channels. I cannot weld them because being able to open and close the part is a critical design feature. Gaseous Nitrogen is the fluid.

Sealing between the channels is not necessary.