Do crankshaft rotate at constant speed in an IC engine for a given RPM after application of flywheel? If not, then how do we get constant speed at vehicle wheel?

3 Answers

The purpose of the flywheel is basically twofold:

to keep enough rotational energy to get to the next power stroke. Think how big a single cylinder flywheel can be.

it is also a suitable place for a clutch.

The fluid flywheel for an auto box also provides the same mass for 1.

As for constant speed, how do you get a vehicle to accelerate - by changing the engine speed.

- 14,798

- 1

- 19

- 29

-

What about on some particular RPM? – Kane Jan 30 '22 at 19:32

-

Why do you think that changes my answer? @RajivKumar Of course you could consider a dmf, but that is still designed for vibration. – Solar Mike Jan 30 '22 at 19:40

-

What I am trying to ask is, 4 stroke IC engine produces huge power in one stroke and then no power in other three strokes. So don't this should result in non uniform velocity of piston and hence crankshaft? Do flywheel nullifies the whole variations or just minimizes it? – Kane Jan 30 '22 at 20:02

-

The piston always has a non-uniform velocity - at 2 points it is zero, but can you tell me when the piston is at maximum velocity? Then, why do tou think there is a firing order, also how many crank revolutions are needed for the complete four-stroke cycle? And @Kamran don’t answer. – Solar Mike Jan 30 '22 at 20:25

The crankshaft is directly connected to the flywheel.

Meaning it does not rotate at a constant speed. It helps regulate the spin of the engine and also it has a tiny amount of wobble due to the small flexibility of the crankshaft.

The engines are designed to spread around the cylinders so that the effect of sudden jerk due to ignition is damped evenly by the drag of the aspiration of the other cylinders, nonetheless, there will be shocks that will be transferred to the flywheel.

And even in the smoothest engines, one could see the vibrations of the engine. But downstream of the power link there are springs in the clutch or transmission and the engine mounts that compensate for these.

- 21,714

- 2

- 18

- 38

-

And the "vibration damper" , a weight at the front of the engine ( I expect IC engines still have them) . And a few engines ( GM Vortec) have a rotating shaft like a camshaft whose only purpose is to balance the engine. – blacksmith37 Jan 30 '22 at 22:11

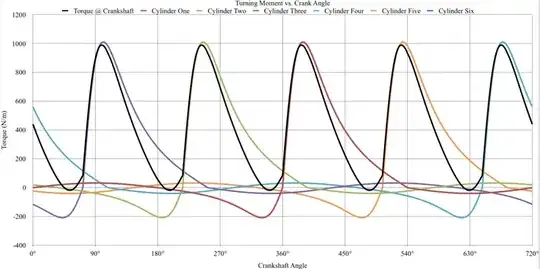

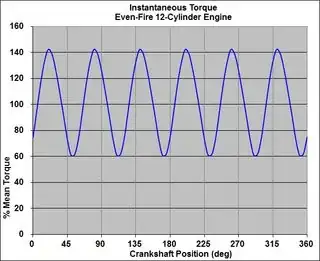

The angular velocity of the crankshaft does not remain constant throughout the rotation. In the following image is the torque at the crankshaft for 360 degrees

Figure: Torque at crankshaft (source:Physics Forums)

The angular acceleration $\alpha$ changes with the torque with the following formula $$\alpha = \frac{M}{I}$$

Where, $I$ is the mass moment of inertia of the rotating masses (crankshaft, flywheel, drivetrain etc).

The higher, $I$ the less is the effect on the angular acceleration. So, with additional mass of the flywheel you tend to have less angular accelerations, i.e. less vibrations.

Perception

Additionally, the reason that its not easy to perceive the changing torque, is that an engine usually operates in the order of 1000 - 6000 rpm, which is something in the order of 10 to 100 revolutions per second. At this rates it is very difficult to perceive the angular momentum changes given that in most cases that rpm is held constant the car is driving on a level ground, and so usually there is no need to increase the torque too much (if torque is kept minimum then the angular acceleration is small).

One of the few occasions that this might become more evident is when the car engine is gradually stalling -- e.g. when going uphill with a relative small gas throttle. In that case the car will be seeming to vibrate more as the engine stalls.

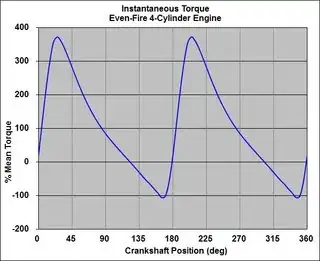

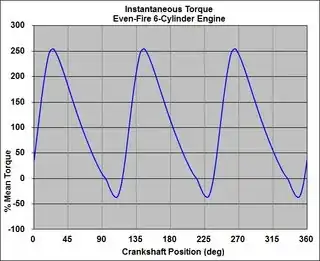

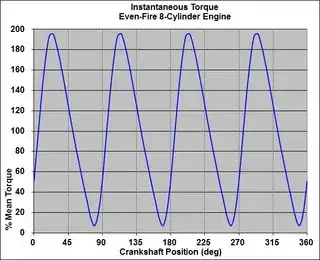

(Sidenote) increasing no of cylinders

With increasing no of cylinders, the torque variation becomes (usually) less. So for comparison purpouses (see http://www.epi-eng).

- 23,917

- 2

- 30

- 72