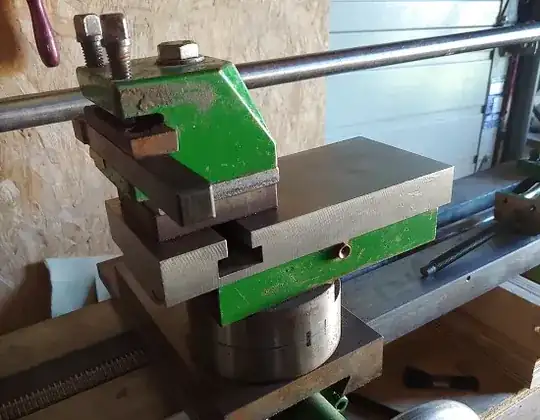

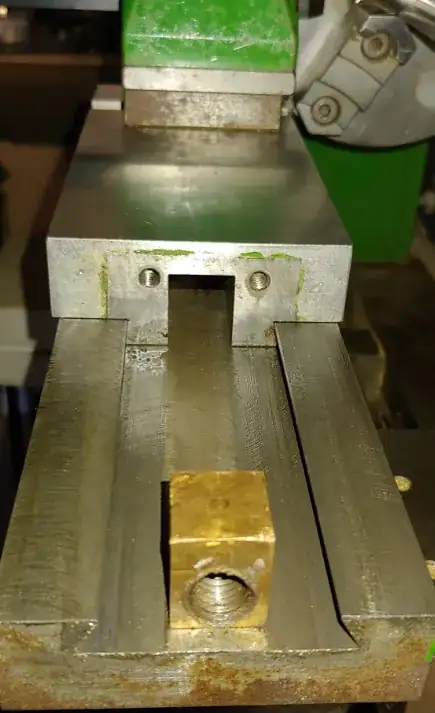

I have some unwanted movement (slack? I don't know if this is the right word due to translating) on my Lathe its chisel holder between the dovetail joint between the gray area and the green area (green area with the brass screw in it). I can move it with my hands and I can feel theres some movement inside the dovetail joint. I would like to fix it so that it is abit more stable.

My question is:

Ts there anything I can do to stop the movement?