I have a spefific problem which I tried to solve with Ansys Fluent and Transient Structural but I did not manage to get a solution so far. I am happy for any kind of help.

I want to press a block of viscous fluid onto a surface with some structural elements on it. The pressure should be applied via a stamp and I want to specify the pressure (not the velocity or displacement of the stamp). The stamp and the structure are very stiff and should not deform significantly.

I am new to Ansys but I tried to set up a coupled system between Transient Structural and Fluent. However, I don't know if this modeling approach can work as I think it should.

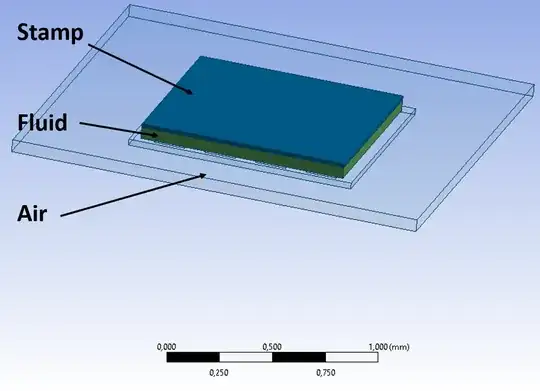

The geometry of my model looks like this so far:

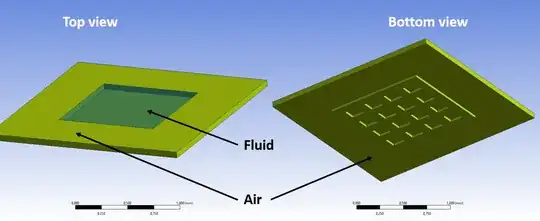

Top and bottom view (without the stamp):

Top and bottom view (without the stamp):

I also modelled the interface between the stamp and the fluid as extra component so I can access it for the system coupling.

The idea is that the fluid should be pressed into the cavities on the surface which are initially filled with air (or vacuum if this is somehow possible to model).

I also modelled the interface between the stamp and the fluid as extra component so I can access it for the system coupling.

The idea is that the fluid should be pressed into the cavities on the surface which are initially filled with air (or vacuum if this is somehow possible to model).

The resin and air parts are set up in Fluent (where the stamp is suppressed): I assigned the materials to the respective cell zones. I defined a Dynamic Mesh at the interface between stamp and fluid and set it to "System-coupling". I set the solution method scheme for "Pressure-velocity-Coupling" to "coupled" and defined the time steps.

The stamp is modelled in Transient Structural where the air and fluid parts are suppressed. I just applied a constant pressure on top of the stamp so that it presses the fluid as well as some frictionless supports on the sides to prevent horizontal movement. The interface between stamp and fluid is set up for system coupling. Time steps are defined the same as in Fluent (this gets overwritten by System Couling anyways but still...)

Gravity is turned off in both Fluent and Transient Structural.

In the System Coupling modul I set up the time steps as well as the data transfers between stamp and fluid. The stamp gets force as an input from the fluid and the fluid gets displacement as an input from the stamp.

Everything in Transient Structural, Fluent and System Coupling is now checked green. When I start the analysis it instantly stops with the error message: "(DP 0) Solver pivot warnings or errors have been encountered during the solution. This is usually a result of an ill conditioned matrix possibly due to unreasonable material properties, an under constrained model, or contact related issues. Check results carefully."

I don't think that the material properties are the reason. I used structural steel from the database for the stamp and liquid water for the fluid (I raised the viscosity to 100 Pa*s).

If you have any advice, I would be grateful. As already mentioned, it could also be that the model setup generally does not work with this method. If you need more information please let me know.

Thank you, Chris