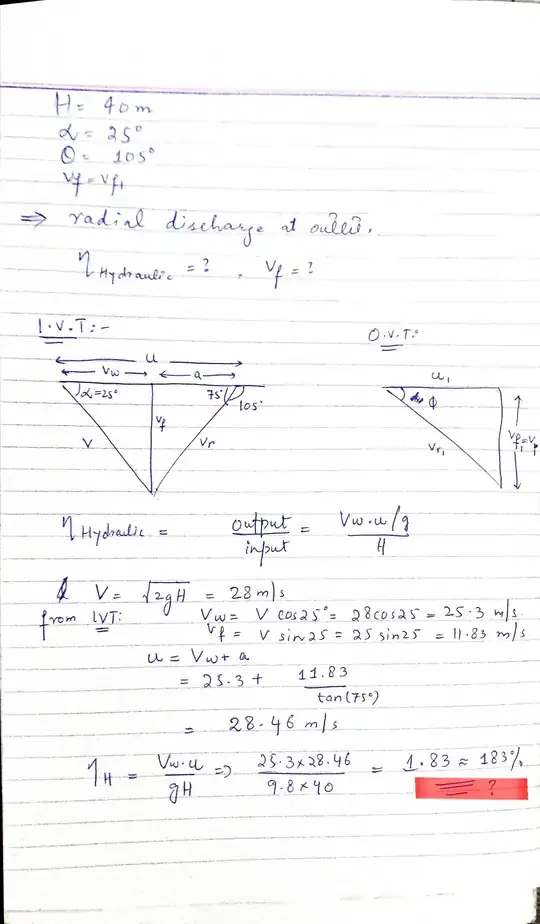

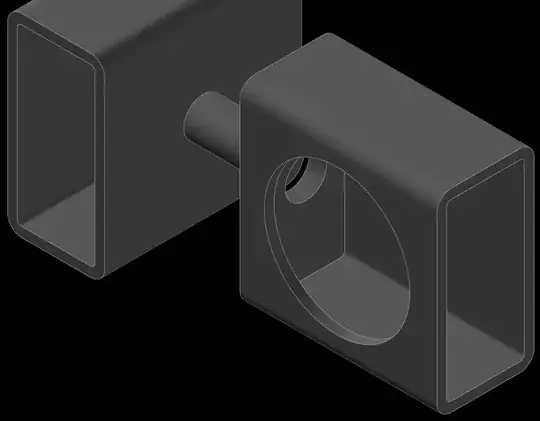

I want to build a DIY case with the connector shown in the pictures below.

As you can see, it consists of a circular plastic that extrudes from the main enclosure. Inside there is something that can be described as "cut_circle", that again extrudes from the main enclosure.

Inside the "cut_cirle" are two holes where power connectors are inserted.

I am not sure if this could be achieved with injection moulding - since i am complete new to the topic.

Even if the two holes inside the "cut_cirle" cannot be made with injection moulding (i am not stating, i do not know, i am also asking), then i guess they could be cut with a drill and connectors could be installed inside (with a press or something).

So, my question is, is this design doable with injection moulding?