Mostly a variation on this question. I have a circuit with a vacuum pump and an air line (used for blowing).

More or the less it works this way: first of all the target is blown with air (to remove dirt) and then (after being closed by the user) vacuum is done in it (after that fluid is suctioned in but that's irrelevant).

The idea would be to use vacuum solenoid valves (even pilot operated since I already have a compressed air feed). The non-pilot operated (the one I found) only stay closed with a pressure up to 1.5-2 bar (I assume the pressure after that will go over the force from the diaphragm spring or something). When blowing the pressure on the user side of the vacuum could be higher, so I imagine the failure mode would be pressure going back into the vacuum pump.

With external pilot the issue is not there since the pilot line has enough force to keep the valve in position (or so I guess from the datasheet).

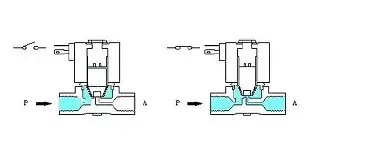

However, as usual, they are expensive. I've seen in similar applications, for vacuum isolation, a combination of really common 2/2 direct action valves; like these if it isn't clear:

They put them back to back so that the two P ports are outside and the two A ports are in the middle. I guess that in this way pressure from one side would try to open one valve but it would be blocked from the other one.

Is this contraption feasible (i.e. it's really reliable?). I've seen vacuum valves that are internally built more or less in that way (they call them double-diaphragm valves) but they still have the pressure side limitation so I have some doubt.

Maybe they work for rough vacuum but with high vacuum they have seal issues? any experience or resource on this?