I have seen 3D freeform tube bending in videos such as this, this, and this. I would like to ask what process is involved in such machines. I can see a swivel mechanism used for bending. What is it called? How exactly does it work? What is the math involved to back-calculate the CNC code / motion in order for any given shape?

-

Why do you think math is involved and the the shape is described by an equation at all involved and that the machine just isn't following the coordinates given to it by the CAM software? – DKNguyen Dec 08 '22 at 17:36

-

Such tube bender is not like a CNC mill or lathe. I don't know if there's any CAM software that is readily available for it. – CaTx Dec 09 '22 at 02:37

1 Answers

This is just regarding math and springback

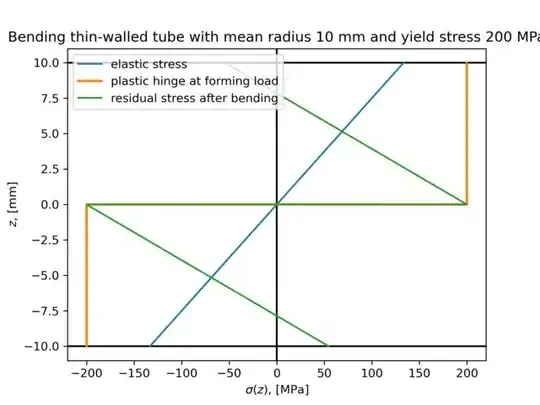

In pure bending, axial strains have a linear distribution through section depending on coordinate $z$ and bend radius $R$:

$$\epsilon(z) = \frac{z}{R}$$

Resulting elastic stress would be simply the strain multiplied by Youngs modulus $E$:

$$\sigma_{el} = E\cdot \frac{z}{R}$$

For bend forming, you need to go into plasticity. Bending with elastoplastic material results in plasticity around elastic core in the section. For bends with relatively small radii, we can assume, that the bending stress at applied loads is fully plastic at yield stress $R_e$:

$$\sigma_{pl} = \begin{cases}R_e & \mathrm{for\;} z>0 \\ -R_e & \mathrm{for\;} z < 0\end{cases}$$

When you remove the loads after going into plasticity, axial strain will go back a little bit with linear distribution through the section $\delta \epsilon = k\cdot z$. So the residual axial stress will be:

$$\sigma_{residual} = \begin{cases}R_e-E\delta\epsilon & \mathrm{for\;} z>0 \\ -R_e-E\delta\epsilon & \mathrm{for\;} z < 0\end{cases}$$

Without the loads, bending moment through the section must be 0, which using symmetry can be written as:

$$\int\limits_0^{z_{max}} z\cdot \left(R_e-E\cdot k\cdot z \right) dA = 0$$

For thinwalled tube with mean radius $r$ and wall thickness $t$, $z = r\cdot \sin(\varphi)$ and $z_{max} = r$:

$$\int\limits_0^{\frac{\pi}{2}} r\cdot \sin(\varphi)\cdot \left(R_e-E\cdot k\cdot r\cdot \sin(\varphi) \right) r\cdot d\varphi = 0$$

From this, you can integrate and end up with expression for $k$ (valid for thin-walled tubes):

$$k = \frac{4R_e}{\pi r E}$$

This constant represents difference between curvature under load and resulting target curvature:

$$k = \frac{1}{R_{load}}-\frac{1}{R_{target}}$$

So if you want to transform straight tube into shape with mean radius $R_{target}$, you need to bend it to mean radius $R_{load} = \frac{1}{1+\frac{1}{R_{target}}}$ first.

This is based on many simplifications, in reality it may be better to determine springback using tests.

- 703

- 5

- 9

-

So if I have a certain profile, I have to program the position of the bending orifice (is this the right term?) using that $R_{load}$ in that formula above right? Where can I find more info on this topic? Is there a book you can recommend? – CaTx Dec 11 '22 at 12:42

-

1That is basically right. Regarding a book recommendation, I cannot help you much. This calculation is the simplest analytical approach you can take when calculating springback. It is possible, that equations useful in reality would be more much more complicated and are not used much in practice. Even for a precision machine like the one in your question, it may be easier to do a few tests with certain tube type to determine real springback experimentally. – Tomáš Létal Dec 11 '22 at 13:28

-

@TomášLétal The trick then is how you actually do those measurements on the workpiece to ensure a weird 3D pipe is within spec. No reference surfaces or anything. I'm not even sure how you would do it with a CMM. I guess you would need a custom fixture. – DKNguyen Dec 11 '22 at 21:30

-

@DKNguyen I think you can do measurements of a tube from the batch with simple bends (maybe even using different bending machine) and then apply it for 3D bends with a tube from the same batch. If simpler approaches fail, I think this could be simulated using FEA quite feasibly. – Tomáš Létal Dec 11 '22 at 22:08

-

1@TomášLétal You can do that to set figure out how to set the machine up for a part, but if you're doing inspection then you need to somehow measure the part itself. – DKNguyen Dec 11 '22 at 22:22

-

-

1@CaTx I think limiting factor could be heat generation from the plastic deformation but also from friction on guiding elements. Also the longer the part of the tube is out, the less quickly you may want to swing it around as this also add to forces on some elements and in very extreme case you could cause additional undesired bending. – Tomáš Létal Dec 12 '22 at 16:17