I think that the most useful answer to your question is that, in practice we are most concerned about the relative torque between two linked shafts.

To put it another way the forces on gears are only of interest to people who design gears and if you are designing a gearbox it's the ration of torque/RPM which is of primary interest.

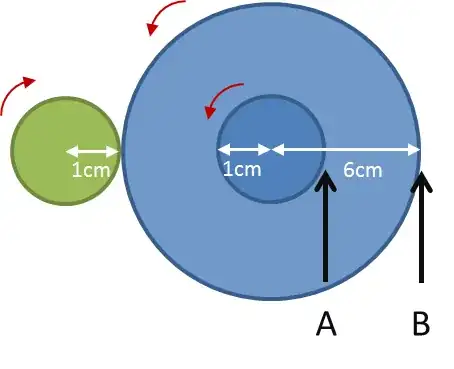

In your example shaft Shaft B will see 6x the torque of shaft A and rotate at 1/6 RPM. At this point the diameter of the smaller gear on shaft B is irrelevant until we know what it is coupled to.

Having said that you are correct in saying that the ratio of torque between shaft A and shaft B is 1:6 and the ratio of angular velocity(RPM) is 6:1 ie shaft B has 6 time more torque and rotates at 1/6th of the speed.

For it to be true compound gear train you also need a shaft C coupled t the smaller gear on shaft B.

If the gear on shaft C was 6cm in diameter then you would have a final drive ratio of 1:(6x6) ie 1:36