Background

In the world of bicycle motocross, also known as BMX racing, gearing is a hotly-debated topic.

Since the bikes are all single-speed, gear ratio is a fixed number defined as chainwheel / cog (front gear divided by rear gear). Altering your gear ratio is understood as an immediately-noticeable tradeoff between acceleration and top-end speed.

Here is a series of common gear ratios:

╔════════════╦═════╦════════╗

║ Chainwheel ║ Cog ║ Ratio ║

╠════════════╬═════╬════════╣

║ 43 ║ 16 ║ 2.6875 ║

║ 41 ║ 15 ║ 2.7333 ║

║ 44 ║ 16 ║ 2.75 ║

╚════════════╩═════╩════════╝

In 2012, a company called Rennen Design Group created a supposed breakthrough innovation called "decimal gearing". The claim is that through manipulations of tooth profile and ring diameter, in-between gear ratios can be created - for example:

╔════════════╦═════╦════════╗

║ Chainwheel ║ Cog ║ Ratio ║

╠════════════╬═════╬════════╣

║ 43 ║ 16 ║ 2.6875 ║

║ 45.7 ║ 17 ║ 2.6882 ║

║ 37.7 ║ 14 ║ 2.6929 ║

║ 43.1 ║ 16 ║ 2.6938 ║

║ 41 ║ 15 ║ 2.7333 ║

║ 41.1 ║ 15 ║ 2.74 ║

║ 52.2 ║ 19 ║ 2.7473 ║

║ 44 ║ 16 ║ 2.75 ║

║ 44.2 ║ 16 ║ 2.7625 ║

╚════════════╩═════╩════════╝

Note: Table is not exhaustive.

For example - a 44.2 tooth gear actually only has 44 teeth, but the tooth spacing, tooth profile, and chainwheel diameter is supposed to have been manipulated to create a larger gear.

In the world of BMX racing, the existence of in-between gear ratios like this is a Really Big Deal. Since the man behind Rennen has a Master's from MIT - and since most BMXers would rather hit jumps than do math or measure things - nobody has really ever checked up on whether or not this is valid. Some questions were asked a long time ago in the dusty corners of a BMX forum, but the testing methods didn't properly control for all variables and the thread descended into a bunch of name-calling and ad-hominem attacks.

The Actual Question

Is this physically possible?

I understand "gear ratio" to be defined as:

For a given gear ratio

x / y, one rotation of the gear withxteeth will result inx / yrotations of the gear withyteeth.

For a gear ratio of 44/16, one full rotation of the 44 tooth gear (chainwheel) should result in 2.75 rotations of the 16 tooth gear (cog).

So for a "decimal ratio" of 44.2/16, one full rotation of the 44.2 tooth gear (which again - only has 44 teeth) is supposed to result in 2.7625 rotations of the 16 tooth gear.

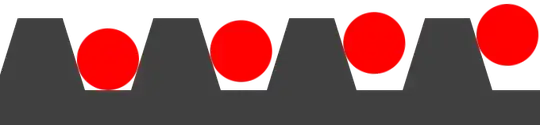

My biggest reservation is the fact that a chain-driven drivetrain is a TIMED DRIVETRAIN. No matter how big or small you make the teeth on the chainwheel, if they fit the chain, they're only going to push as many links through per rotation as the chainwheel has teeth.

For a true 44.2 tooth chainwheel, one would expect that 442 links get pushed through over 10 full rotations of the chainwheel - but that's not the case. Only 440 links will ever get pushed through to the cog because only 44 links get pushed through per full rotation of the chainwheel. I actually spent my whole afternoon yesterday taking video and counting links and measuring.

But I'm not a scientist. My high school didn't even offer a physics course. I'm just a racer that trains really hard and knows how to do basic math.

If this were a belt-driven system, I would completely understand how a manipulation of the chainwheel diameter would change the effective ratio - but it's not. It's a timed drivetrain, limited by the physical dimensions of the chain.

I have several hundred dollars and months of training and metrics invested in these stupid chainwheels. If someone could confirm or deny my theories, I would really appreciate it. I just want some closure.

Here's a photo of the teeth from a 41 tooth chainwheel on top of the teeth from a 41.2 tooth chainwheel - both are Rennen gears:

Here's a 41t on top of a 41.2t:

Here's the 41.2t on top of the 41t, from behind: